Successful sales with proper labeling

Ensure a fast logistics flow and growing customer trust with a proper labeling system.

Leave your contact details, and our manager will contact you within one hour.

All customs clearance details are on us

Professional solutions for e-commerce

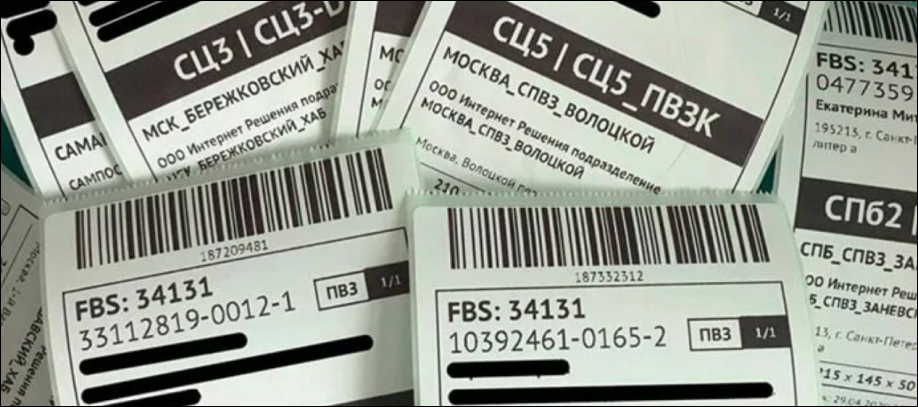

Proper product labeling determines the speed of order processing and the quality of logistics operations. Sellers who comply with labeling requirements gain advantages such as fast delivery and a reduced number of returns. The labeling system affects the seller’s rating and the level of customer trust. A well-structured approach to label design saves time in warehouse operations.

TTL provides comprehensive services for organizing logistics processes for online stores.

Modern marketplaces set strict standards for working with suppliers. Failure to comply with labeling rules leads to fines and blocking of product listings. Professional delivery labeling ensures accurate parcel sorting in warehouses. High-quality labels contain all the necessary information for quick product identification.

Labeling for sellers: basic rules

Product labeling is not just a sticker on the packaging, but an essential element of the marketplace logistics system. It ensures fast identification, sorting, tracking, storage, and delivery of goods. To ensure that products are accepted and processed without delays, sellers must comply with a number of mandatory requirements:

- Unique code — a barcode or QR code automatically linked to the product card in the system (OZON, Wildberries, Yandex Market, etc.).

- Information content — SKU, product name, weight, dimensions, storage conditions, and marketplace code.

- Format and placement — the label must be placed on a visible area of the packaging and must not cover seams or joints; standard sizes: 58×40 mm (for small items), 100×150 mm (for large goods).

- Quality and materials — at least 300 dpi, thermal transfer printing on a polypropylene label with acrylic adhesive (or removable backing if required).

- Warning symbols — for example, «Fragile», «Do not drop», temperature indicators (for cosmetics, food products, pharmaceuticals).

Compliance with these requirements helps speed up acceptance and sorting of goods in warehouses, reduce errors, and avoid fines or returns.

Features of product labeling for sellers

Different product categories require specific labeling approaches. Clothing is labeled with size, fabric composition, and care instructions. Electronics include information on warranty service and certification. Food products contain data on expiration dates and storage conditions.

It is worth noting: «According to Wildberries statistics, properly labeled products are processed 40% faster than items with labeling violations».

Fragile goods require additional warning signs. Symbols such as «Fragile» or «Do not drop» are placed next to the main label. Liquids and aerosols are labeled with special hazard symbols.

Temperature requirements are indicated for products sensitive to temperature fluctuations. Cosmetics and pharmaceuticals include storage temperature information. Frozen products are labeled with appropriate symbols.

What requirements marketplaces set for labels

The print quality of labels affects the speed of product processing in the warehouse. Thermal transfer printing ensures resistance of the image to moisture and abrasion. The print resolution must be at least 300 dpi for clear display of fine details.

The label material is selected depending on operating conditions. Polypropylene labels are suitable for goods with a long shelf life. Paper options are used for fast-moving items.

The adhesive layer must ensure reliable fixation without damaging the packaging when removed. Acrylic adhesive is suitable for most surfaces. Removable labels are used for products that require relabeling:

- Seasonal products with changing characteristics.

- Items with dynamic pricing.

- Products requiring additional information.

Quality control of labels is carried out before goods are sent to the warehouse. Barcode readability, information accuracy, and print quality are checked. Defective labels are replaced before the goods enter the logistics system.

Automation of the labeling process

Modern warehouse management systems are integrated with label printers for automatic label generation. The software creates labels based on data from the accounting system. This eliminates errors caused by manual data entry.

Automatic applicators apply labels to products without human involvement. The equipment is configured for specific packaging sizes and labeling requirements. Productivity reaches up to 60 labels per minute with high positioning accuracy.

Integration with marketplace systems allows receiving up-to-date labeling requirements in real time. Seller labeling is automatically adapted to changes in marketplace rules. The system tracks updates and adjusts label templates.

Quality control is carried out using machine vision. Cameras verify correct label placement and print quality. The system automatically rejects products with labeling defects.

Logistics advantages of proper labeling

Accurate labeling speeds up the acceptance process of goods at marketplace warehouses. Warehouse staff spend less time identifying items. This reduces queues during intake and accelerates the time products go on sale.

Automated sorting works more efficiently with properly labeled products. Scanners read information without additional operations. Seller labeling for Ozon must comply with the platform’s technical requirements to ensure correct processing.

Reducing the number of errors during order picking improves the level of service. Customers receive exactly the products they ordered. This reduces the number of returns and claims:

- Reduced time spent resolving disputed situations.

- Increased customer loyalty.

- Improved seller reputation.

Labeling analytics help optimize logistics processes. Data on processing times for different product types are used for supply planning. Statistics on labeling errors identify weak points in the product preparation process.

A professional approach to product labeling ensures stable operation of an online store. Investments in high-quality equipment and staff training pay off by increasing the efficiency of logistics processes. TTL offers comprehensive solutions for organizing product labeling for sellers of all levels.

Contacts

Leave your contact details, and our manager will contact you within one hour.